About us

- Company profile

- Technical Innovation

- Order service flow

- Screw barrel parameters

- SKD inlay bushing barrel

- Screw barrel process flow

- Exhibition

About us

- Address:NO.1 Liuhang Road, Xihou Industrial Zone, Jintang Town, Dinghai District, Zhoushan

- TEL:86-580-8052288

- FAX:86-580-8053878

- ZIPCODE:316031

- E-mail: info@hcscrew.cn

- URL:www.hcscrew.cn

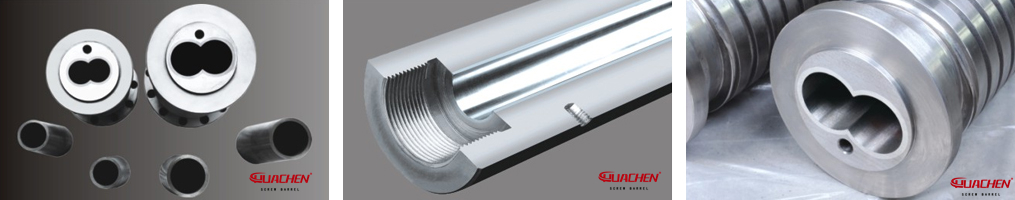

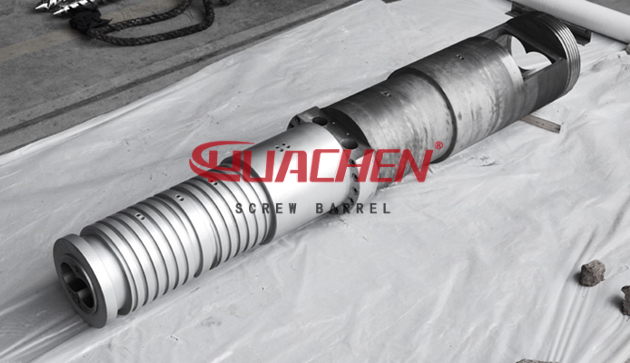

SKD inlay bushing barrel

SKD inlay bushing barrel, SKD sleeve fitted barrel, or SKD sleeve insert barrel

In 2012, HUACHEN Screw developed a conical twin screw barrel with a tool steel SKD sleeve or bush inserts to resist corrosion and wear. We use the wear-resistant material SKD to make a conical-eight-shaped bore sleeve, which is then inlaid into the bore of the conical twin barrel to ensure that it fits closely with the inner wall. Due to the conical twin barrel’s low wear resistance, it is especially suitable for producing high filled PVC products.

This highly wear-resistant base material is typically made from the tool steels SKD11(D2) and SKD61(H13). The Chinese market refers to it as SKD screw barrels or SKD sleeve fitted barrels for a complete set of twin screw conical barrels with an SKD barrel.

SKD sleeve fitted barrels are high performance barrels with a challenging machining process. The entire barrel bore must remain flat and smooth throughout, with no gaps. This is to prevent the barrel bore from sticking to the material and affecting the plasticisation of the polymers. This means that the inlay plane of the SKD inner bushing must be flat and smooth, which is also a technically difficult point to process. The SKD11 sleeve is embedded in the inner wall of the barrel extruding section. When producing highly filled PVC products, the barrel extruding section is most likely to wear out. According to the range of areas where wear resistance is required, the SKD11 sleeve fitted barrel is available in three different lengths: the one-stage SKD barrel, the two-stage SKD barrel, and the full-stage SKD barrel.

SKD sleeve fitted barrel (SKD inlay bushing barrel) from HUACHEN Screw Barrel Factory

Experience the advantages of the SKD sleeve fitted barrel from HUACHEN Screw Barrel Factory

1. The wear-resistant SKD11 sleeve is tightly bonded to the barrel, so no alloy layer is lost.

2. Improved corrosion resistance

3. Improved wear resistance

4. Increased surface hardness of the barrel bore

5. Suitable for extrusion of high filled materials, effectively extending the range of materials processed

6. High productivity and energy saving, reducing production costs

Click here to see the actual results.

1. Wear Resistant Barrel Sleeve, SKD Sleeve or Bush

3. Removable SKD Sleeve Fitted Technology for Conical Twin Screw Barrel

4. Difference Between SKD11 And SKD61 On Process Screw Barrel