How To Solve Black Lines On Rigid And Semi Rigid UPVC Products

Date:2022-7-28 Author:hcscrew

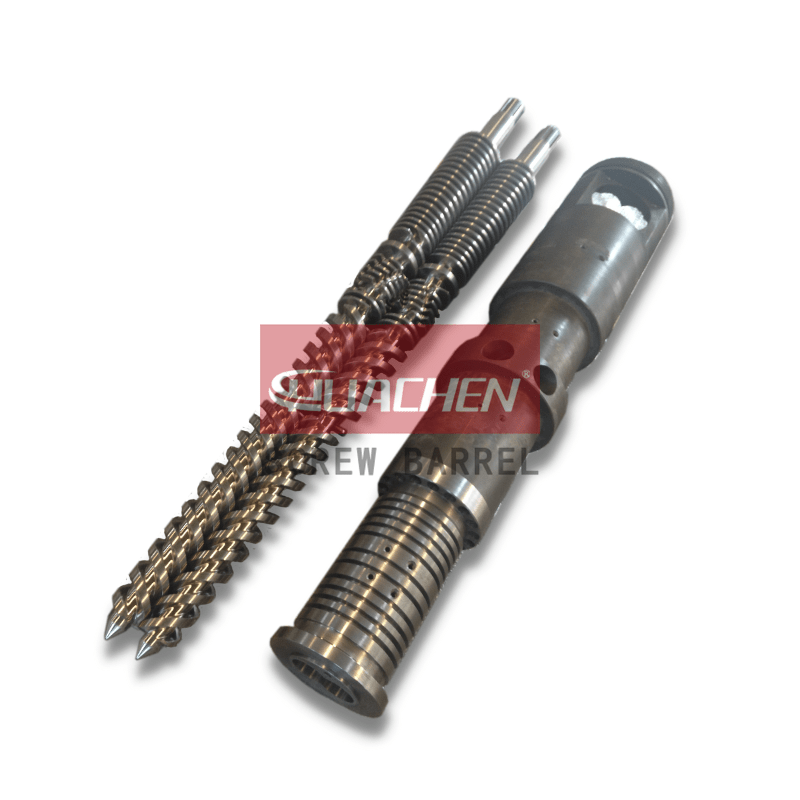

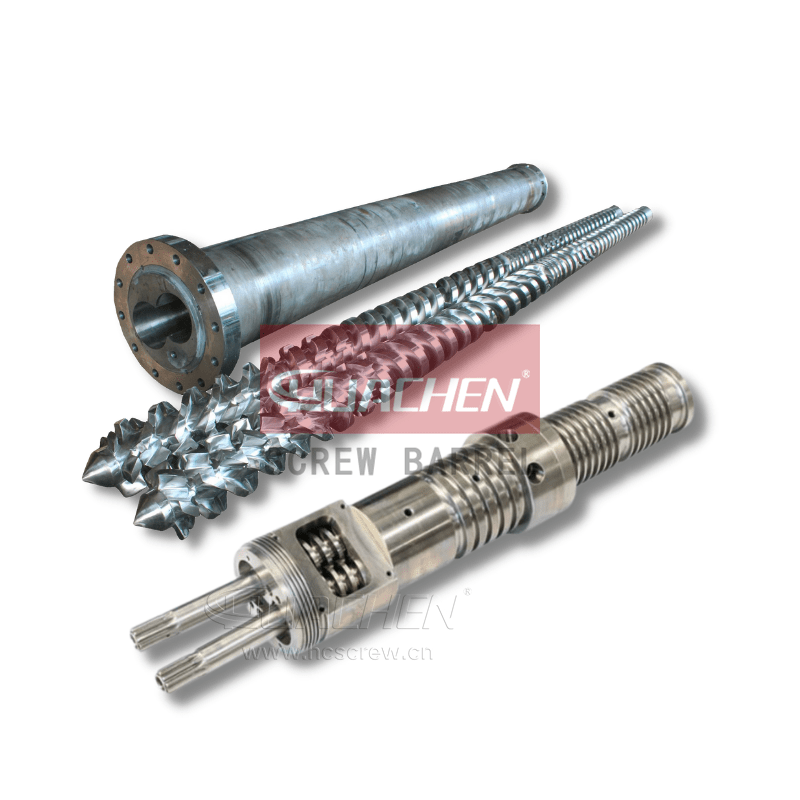

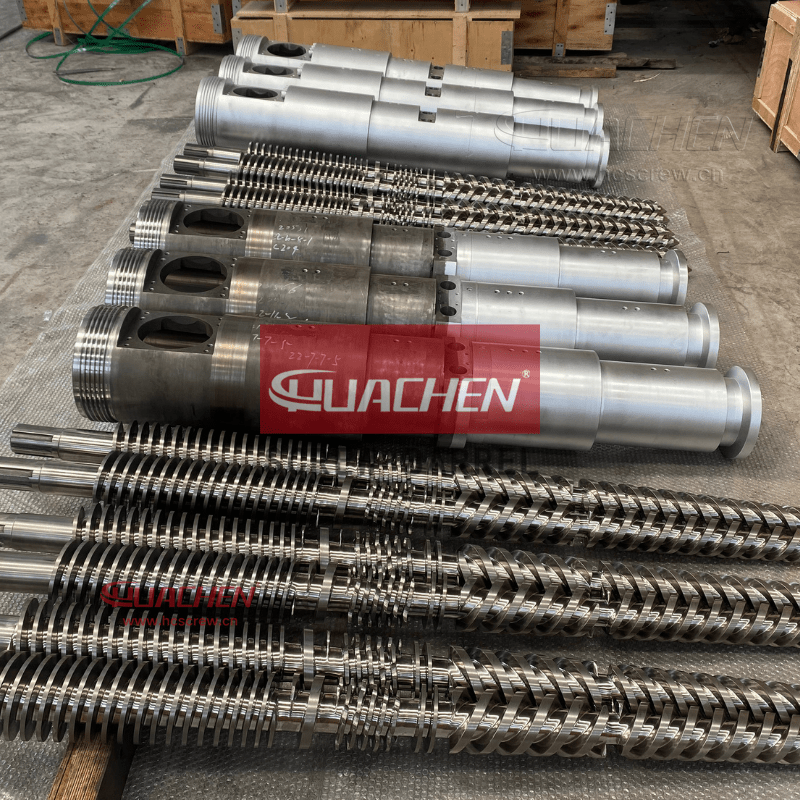

Since HUACHEN began manufacturing PVC screw barrels many years ago, it has gained extensive experience in the user market. HUACHEN’s technicians have discovered some solutions to the problem of black lines in UPVC products while manufacturing, installing, and maintaining UPVC screw barrels. We wish to raise this matter in order to increase our customers’ knowledge and experience.

01: What is semi rigid PVC?

Semi-rigid PVC is also known as FPC. It is made from polyvinyl chloride resin by adding stabilisers, lubricants, and other additives before it is kneaded, rolled, plasticised, granulated and extrusion moulded. PVC electrical conduit is a semi-rigid plastic pipe.

02: What is rigid PVC?

Rigid PVC, also called UPVC, contains polyvinyl chloride, impact modifiers, heat stabilisers, lubricants, fillers, colours, etc. There are many uses for UPVC, including pipes, boards, profiles, chemical building materials, plastic doors and windows, and decorative products. Pipes are the largest application area for UPVC plastic. Aside from its light weight and corrosion resistance, it is cheap and easy to obtain, which makes it ideal for drinking water pipes, drains, sewage systems, and exhaust systems.

03: Analyzing the proportion of black lines on UPVC products

Calcium powder filling determines the proportion of the black line. The higher the filling of calcium powder, the higher the proportion of black lines. We suspect that calcium powder on the screw and screw barrel wear is the most likely source of suspicion.

1. when the recipe uses calcium powder high in filling:

Calcium powder‘s fineness will decrease. Generally, calcium powder mesh refers to one side of the sieve, so it is cubic in calculation. As a result, increasing from 400 to 800 mesh is a ratio of 8 times, not twice. Calcium powder becomes coarser and wears out screw barrel more quickly. If the UPVC formulation does not contain lubrication, it is difficult to avoid abrasive black lines.

2. Calcium powder hardness:

There is an obvious wear on the screw if the calcium powder contains a significant amount of silica. Screws are more likely to detect silica and magnesium silicate, according to the experiment. When testing the machine, white cement proved to be the most abrasive. This test only used calcium powder to increase the stiffness of the rings. It was not deliberate to choose this type of filling material. UPVC product formulations should avoid using white cement as calcium powder. Additionally, adding small amounts of untreated talc can result in black lines. If the original product already has black lines, this can be exacerbated. The hardness of the calcium powder also affects the appearance of black lines.

04: Formulations containing lead in UPVC

This problem also occurs when using CPE with stabilisers in UPVC formulations, although the black line is relatively light. Our technicians have experienced a similar problem. UPVC melt with black lines is brought out of the barrel when the conical twin screw is unscrewed from the extruder adaptor mounting area. In spite of replacing the screw with a replacement one, the molten UPVC with black lines continued to appear. Our trial run of 7 days finally revealed that the problem was with the CPE, which could be fixed by replacing it. Most likely, CPE pickling failed. It is important to note, however, that this is a rare occurrence. Nevertheless, this case remains interesting.

05: Extrusion equipment problems.

1. The screw nitriding did not meet the specifications of the UPVC product, and the nitriding layer was not standard. If you don’t replace the screw with one that meets the standard, the issue is difficult to resolve. You can also adjust the UPVC raw material formula to suit the screw.

2. This is a rough screw and barrel job. This is easier to identify, it is the black line that appears only after the screw barrel is replaced. As production continues, the proportion of black lines on UPVC products reduces and becomes lighter.

3. This is due to severe wear on the screw.

4. Extruder gearbox and conical twin screw lead to black lines. Both of these triggers are unusual. In some extrusion machines, spline bushings that fit too tightly on the screw barrel will result in black lines. Please note that this does not imply that the gearbox is in poor condition. This gearbox has a standard distribution box, it depends only on the tolerances applied during machining. As a result, the screw barrel installer must know that the screw’s spline sleeve cannot be too tight, or it must be constantly perfected during installation.

06: Problems related to processes and plasticization.

More black lines result from poor plasticization. In the conical screw’s fourth zone, the pressure is highest when the UPVC melt is plasticized between the screw and the barrel. The fourth zone of the conical screw, the small head area of a conical twin screw, has the highest friction.

If the plasticization process is incomplete, the UPVC melt may still be a rigid or hard powder. Black lines will appear on the screw as a result of material friction. Friction will be reduced if the UPVC material is slightly softer. When the screw’s plasticization is poor, calcium powder will wear the screw directly, causing friction in the screw’s fourth zone. It is naturally difficult to avoid black lines. Plasticisation is also low if the screw is poorly nitrided. It is possible that the product will appear as a rippled black line in severe cases. As a result, the black lines on this UPVC product will be evenly spaced on top and bottom.

07: Providing an emergency solution

As soon as we can determine what is causing the black line. Getting an emergency solution to production methods is possible. If continuous debugging hasn’t solved the black line problem, then it’s usually the screw. In this case, we can use talc (magnesium silicate) directly in the recipe at a rate of 5 parts per addition. The black line will initially be visible after adding talcum powder, as the screw barrel wears out. After that, talcum powder could be removed from UPVC formulas. The talcum powder will polish the screw barrel, temporarily removing the black line, thus fighting poison with poison.

Summary

The above are only emergency solutions HUACHEN Screw has encountered when providing screw barrel repair and maintenance services to customers. We would be glad to hear from you if you have any more experience or solutions available for solving black lines in UPVC. It is our hope that this article will help most UPVC product manufacturers find more solutions to their problems.

YOU MAY ALSO LIKE

| PVC Screw Barrel ↗ Get details and latest price of PVC screw barrel, high output, PVC single, parallel, conical twin screws, advantages, applications at HUACHEN… |

| RPVC, CPVC, UPVC Screw Barrel ↗ Get details and latest price of RPVC, CPVC, UPVC screw barrel, high-speed design, better anti-wear and anti-corrosion screw barrel at HUACHEN… |

More posts about rigid UPVC products

HUACHEN Screw Barrel Recent Post

- Boosting Efficiency and Quality: HUACHEN Screw Barrel’s Unmissable Showcase at HanoiPlas 2023

- Pipe Extrusion Operation: Best Practices for High-Quality Products

- Expert Maintenance Tips for Long-Lasting Bimetallic Alloy Screw Barrels

- Reviving Your Extruder: The Importance of Choosing the Right Screw Barrel Replacement

- Solutions to Common Production Problems for Rigid PVC Profiles and Pipes

- Customized Twin Screw Barrel with Internal Bore Grooves Sprayed with Bimetallic Alloy

- Troubleshooting Vent Flow Material Problems in PVC Profile Formation with Conical Twin Screw Extruders

- A Comprehensive Guide to Popular PVC Profiles and Their Production Methods

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;