About us

- Company profile

- Technical Innovation

- Order service flow

- Screw barrel parameters

- SKD inlay bushing barrel

- Screw barrel process flow

- Exhibition

Contact us

- Address:NO.1 Liuhang Road, Xihou Industrial Zone, Jintang Town, Dinghai District, Zhoushan

- TEL:86-580-8052288

- FAX:86-580-8053878

- ZIPCODE:316031

- E-mail: info@hcscrew.cn

- URL:www.hcscrew.cn

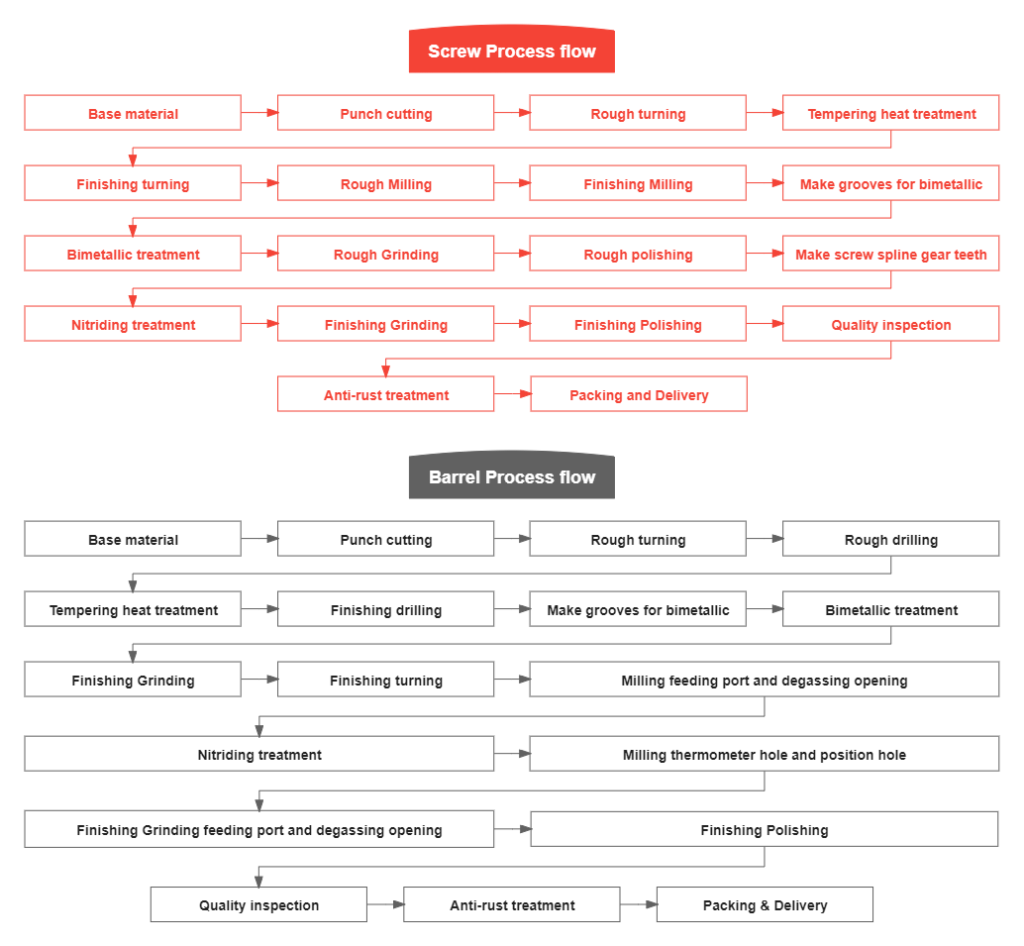

Screw barrel process flow

A high-quality screw barrel requires every detail in the production process!

The screw and barrel are the most important parts of the plastic extruder. It does not only require strict material selection, which must be nitrided steel and cannot be replaced by other types of steel, but more importantly, they must have a strict machining process.

The Standard Screw And Barrel Process Flow For HUACHEN Screw Barrel

What is Tempering Heat Treatment

The complete production time is generally about 30 to 45 days. The key point in processing for HUACHEN screw is aging treatment (artificial aging treatment – tempering heat treatment).

Aging treatment: refers to the nitrialloy after solid solution treatment, cold plastic deformation, or casting treatment. After forging, it is placed at a higher temperature or room temperature to maintain its properties, shape, and size over time tempering heat treatment.

Aging Treatment In Tempering Heat Treatment

If the nitrialloy is heated to a higher temperature, and aged in a shorter time. The aging treatment is called artificial aging treatment.

If the nitrialloy is placed at room temperature or natural conditions for a long time and the aging phenomenon occurs. It is called natural aging treatment.

The purpose of aging treatment is to eliminate the internal stress on nitrialloy, stabilize the organization and size, and improve the mechanical properties.

In order to avoid nitriding screw barrel shape or size changes in the long-term use. HUAHCEN Scerw Barrel Factory would reheat the nitrialloy to 100-150 ℃ in the middle procedure between low-temperature tempering (low-temperature tempering temperature 150-250 ℃) and finishing. The Nitrialloy should remain at the temperature for about 5-20 hours. It is aimed at the stable quality of the screw barrel, known as aging. It is important to do aging treatment on screw and barrel. It helps to eliminate residual stresses, and stabilize steel organization and its dimensions.

A Complete Processing Time Of Your New Screw Barrel

Some extruder users may be very urgent to produce a schedule after ordering a new screw barrel. Some extrusion machinery does not carry out the standard aging treated screw barrel to save costs.

The aging treatment can effectively avoid screw barrel scraping and damage in future use, especially use on extrusion for PVC, PE, and PP materials. So, extruder users should try to order in advance, to give enough processing time(30 to 45 days) to ensure the stable high quality of your screw and barrel.