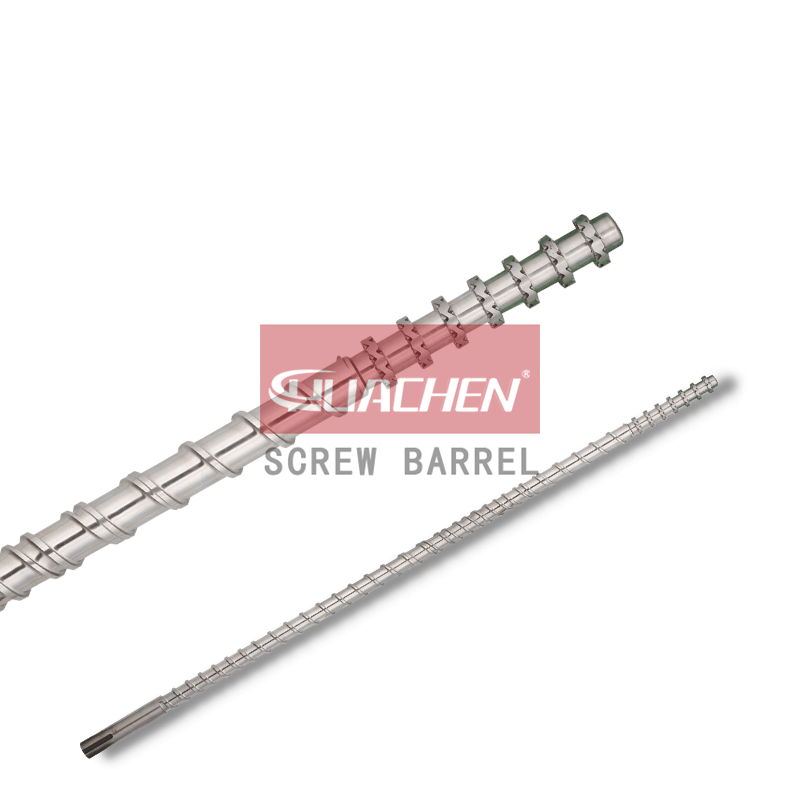

PE PP PVC Plastic Film Single Screw Extrusion Screw Barrel

● PE, PP, PVC, PET, etc.

● Min. Order (MOQ): 1 screw + 1 barrel

● Plastic film making. Blown film, cast film, bidirectional stretching film

● Powder materials. Pellets materials

● Fresh raw materials. Recycled raw materials

● Anti-wear solution: Bimetallic barrel + bimetallic screw, nitriding barrel + bimetallic screw, nitriding screw barrel, chrome coating screw

You Need a Better Plastic Film Extrusion Screw Barrel at Good Price!

- Product Detail

Plastic film extrusion single screw barrel structure, optimised extrusion screw and barrel structure. More life, half the cost.

Quality plastic film single screw extrusion screw barrel for PE / PP/ PVC

1. We make optimised screw barrels for plastic film extrusions. Screw barrels are made of premium alloy steel 38CrMoAlA, tempered, precision machined, and nitrided for superior hardness and corrosion resistance. Every screw barrel is manufactured by a high precision CNC screw milling machine, which can guarantee a high degree of consistency in extrusion performance.

2. Our screw barrel structure can be upgraded for old plastic film producers who can’t meet their production requirements. With an optimised screw structure, we can improve the feeding capacity and plasticising performance of the screw barrel without changing anything else. This produces products with excellent hardness, high brightness, and smoothness. You can install our screw barrels on most models. If you’re not sure of your screw barrel design, our engineers can customise it.

Applications

LDPE film, LLDPE film, HDPE film.

BOPP film, CPP film, IPP film.

Single screw barrel for plastic film blowing extrusion

Single screw barrel for cast film extrusion

Single screw barrel for inflation film extrusion

Screw barrel for bidirectional stretching film machine

Shopping bags, liquid packaging, mulch film, courier bags, stretch film, agro shade net film, agriculture film, lamination film, shrink film, nursery film, surface protection film, and flexible packaging film.

Manufacture of plastic film extrusion screw barrel models

| Model | Screw Diameter (mm) | Screw L/D ratio | Screw speed Max. (rpm) | Motor required (KW) | Output (Kg/h) |

|---|---|---|---|---|---|

| HCS40 | Ф40 | 28/30 | 12-100 | 7.5 | 15-30 |

| HCS45 | Ф45 | 28/30 | 12-100 | 7.5 | 30-40 |

| HCS50 | Ф50 | 28/30 | 12-100 | 15 | 50-60 |

| HCS55 | Ф55 | 28/30 | 12-100 | 18.5 | 60-70 |

| HCS60 | Ф60 | 28/30 | 12-100 | 22 | 70-80 |

| HCS65 | Ф65 | 28/30 | 12-100 | 30 | 80-90 |

*Please check the actual screw barrel design with the salesperson before the order start.

Parameter

1. Material: Premium 38CrMoAlA, UNS K24065, SACM645, 41CrAlMo7-10, nitrialloy.

2. Plasma nitriding layer: 0.6-0.8mm

3. Nitriding time: more than 120 hours

4. Nitriding surface hardness: HV1000-1100

5. Nitrided Brittleness: Less than Grade1

6. Surface Roughness: Ra 0.4μm

7. Screw Linearity: ≤0.015mm

8. Alloy surface hardness: HRC≥61

9. Alloy deepness: 2-4mm

>>Learn more about our plastic film single screw extrusion screw barrel parameters

The ultimate solution for abrasion and wear

Level 3: bimetallic barrel and bimetallic screw;

Level 2: nitrided barrel and bimetallic screw;

Level 1: nitrided barrel and nitrided screws;

Hard chrome coating screw is an optional process.

Barrel with centrifugal casting process is an optional process.

Related plastic film single screw extrusion screw barrel spare parts

1. Extrusion heaters. 2. Barrel blowers or fans. 3. Extrusion motor. 4. Extrusion gearbox for single screw

Trading Term

1. Business type: manufacturer, foreign trade company.

2. Origin: Zhoushan City, Zhejiang, China

3. Warranty: 12 months for fresh material.

4. International commercial terms: FOB, CFR, CIF, EXW

5. Screw and barrel HS code: 8477900000

6. Terms of payment: T/T, L/C

7. Average lead time: stork model in 7 days. Peak season lead time: 45 days, Off season lead time: 33 days

8. Transport package: AA Grade Wooden Case

Production time

Complete set of plastic film single screw extrusion screw barrel within 20-30 days depending on the complexity of the part.

Services

1. Inspection of original plastic film extrusion screws and barrels, and other related components.

2. Providing OEM or ODM-quality rebuilding services.

3. Modification services of plastic film single screw designs to improve melting and mixing performance.

4. Emergency Service for an emergency turnaround service to minimize machine downtime.

About us

HUACHEN Screw has been a leading manufacturer of plastic film single screw extrusion screw barrel in Zhoushan Jintang since 1993. As one of the leading companies in designing and processing plastic machinery replacement parts, HUACHEN Screw can provide its customers with a wide range of services, including drawing rebuilding, design, modification, and customized screw barrels. Our company has also successfully exported and supplied screw barrels to customers worldwide.

>>Learn more about our company

It’s the China Original Factory for plastic film extrusion screw barrels. If you have any questions, please feel free to contact us.