PE Pipe Extruder Conical Twin Screw Barrel

● PE / HDPE / WPC Matrix Polyethylene, virgin or recycled materials

● Large pipe, solid wall pipe, corrugated wall pipe, coil pipe

● Min. Order (MOQ): 2 conical screws + 1 barrel

● Based material: Premium 38CrMoAlA tempered and nitrided

● Anti-wear solution: SKD sleeve fitted barrel + bimetallic screw, bimetallic barrel + bimetallic screw

You Need Better Conical Twin Screw Barrel at Good Price!

- Product Detail

PE products and PE pipes are usually produced using single screw extruders. But HUACHEN Screw and China’s leading extruder manufacturers have collaborated to develop energy-efficient conical twin screw barrels for PE pipe extruders.

This PE pipe extruder conical twin screw barrel has higher conveying efficiency and requires less power to install than a single screw barrel. HUACHEN’s conical twin screw barrels for PE pipe extruder are one of our most popular product lines, and we keep a lot in stock. Feel free to contact us for a quote.

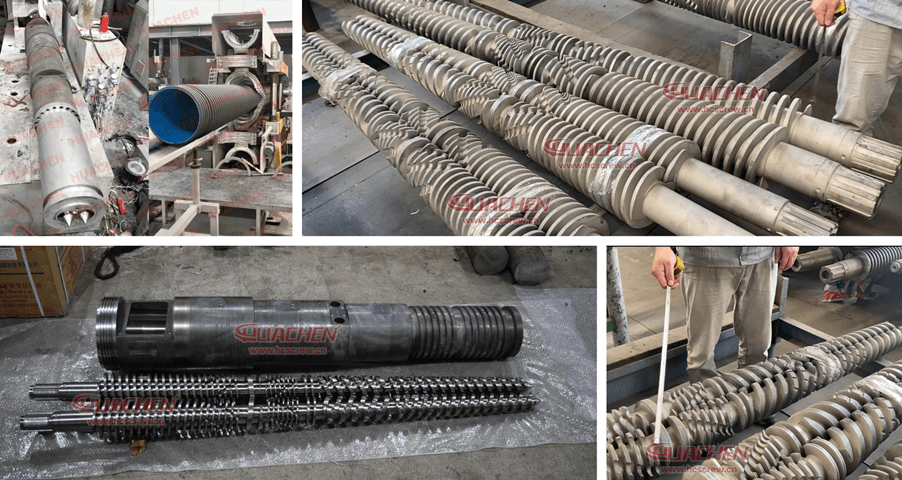

PE pipe extruder conical twin screw barrel

1. Specifically developed for PE pipes and products, the conical twin screw has a special compression ratio and thread configuration. Production can be achieved with powder mix raw material direct extrusion. Compared to a single screw barrel with the same power main motor, a conical twin screw barrel nearly doubles the output. That’s almost 40% less electricity consumed in a year by the extruder, saving producers a lot of money.

2. Conical twin screws designed for PE are low-shear and high-conveyance. Basic output and pipe production speed are much higher than with a single screw barrel, which allows for in-line flaring and other flow operations. The screw barrel set can produce large solid wall PE pipes, double wall corrugated PE pipes, PE winding pipes, and wood-plastic PE sheets.

3. There are venting ports on the conical barrel. It helps overcome the problem of air bubbles on the inside and outside of the pipes because of moisture in raw materials.

4. Improved wear resistance of the screw and barrel. Screw barrel made from high quality 38CrMoAlA, which is rigorously tempered and nitrided. Next, the conical twin screw’s vulnerable parts get bimetallic alloy treatment. We can supply you with SKD sleeve fitted barrel of higher quality. PE pipe conical twin screw barrels offer extremely high wear and corrosion resistance and increased service life.

Application

Conical twin screw barrel for large solid wall HDPE pipe extrusion;

For corrugated wall HDPE pipe extrusion (double wall or single wall);

For polyethylene coil pipe/spiral pipe extrusion;

Conical twin screw barrel for wood composite PE sheet, board extrusion;

Corrugated wall FRPP pipe, Corrugated wall PVC pipe.

Manufacture of PE pipe extruder conical twin screw barrel

| Model | Speed (RPM) | Motor (KW) | Capacity (kg/h) | Screw length (mm) | Barrel length (mm) | Weight (kg) | Package dimension (m) |

|---|---|---|---|---|---|---|---|

| HCZS 80/156 | 34.7 | 55 | 500 | 2116 | 1850 | 775 | 2.2*0.4*0.5 |

| HCZS 92/188 | 34.7 | 110 | 800 | 2805 | 2520 | 1500 | 3.0*0.5*0.6 |

>> We offer standard conical twin screw barrel models and more. All of them use standard assembly dimensions and are easy to install. Get in touch if you want to know more.

Parameters

1) Material: Premium 38CrMoAlA, UNS K24065, SACM645, 41CrAlMo7-10, SKD11; 2) Plasma nitriding layer: 0.7 mm; 3) Nitriding time: more than 120 hours; 4) Nitriding surface hardness: ≥HV1000; 5) Nitriding Brittleness: Less than Grade 1; 6) Surface Roughness: Ra 0.4μm; 7) Screw Linearity: ≤0.015 mm; 8) Alloy surface hardness: HRC≥61; 9) Alloy deepness: 1.5 mm; 10) SKD sleeve surface hardness: HRC≥62; 11) SKD sleeve thickness: 6-10mm.

>>Learn more about our PE pipe extruder screw barrel parameters

The ultimate solution for abrasion and wear

-Level 2, SKD sleeve fitted barrel and bimetallic screws;

-Level 1, bimetallic barrel and bimetallic screws;

Production time

Stork model in 7 days. Peak season lead time within 45 days, and off season lead time within 33 days depending on the complexity of the part.

HUACHEN Screw has been a leading conical twin screw barrel manufacturer in Zhoushan Jintang since 1993. HUACHEN Screw can provide its customers with a wide range of services, including drawing rebuilding, design, modification, and customized screw barrels. We have also successfully exported and supplied screw barrels to customers throughout the world. We are the China origin factory of PE pipe extruder screw barrel. If you have any questions, please feel free to contact us.