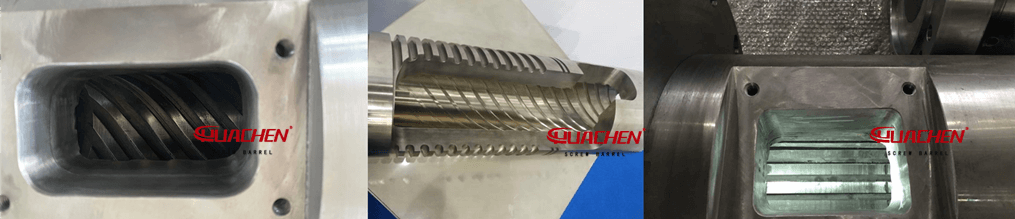

Grooved Feed Barrel Sleeve

● Sale and assembly with high speed extrusion barrel

● Pipes extrusion

● Sheets extrusion

● Recycling pelletizing extrusion

● PE / HDPE / PP

You Need Better High Speed Extrusion Grooved Feed Barrel at Good Price!

- Product Detail

HUACHEN Screw has been a leading Grooved Feed Barrel Sleeve manufacturer in Zhoushan Jintang since 2005. With many years of experience in the design and processing of plastic machinery accessories, HUACHEN Screw can provide its customers with a wide range of services, including screw barrel design, rebuilding, modification, and upgrade. Our company has also successfully exported and supplied screw barrels to customers worldwide.

>>Learn More About Our Company

Grooved Feed Barrel Sleeve

It’s not possible to buy the grooved feed barrel sleeve separately, which is an integral part of the high-speed screw barrel.

This barrel has an inner wall with a groove ranging from 30 mm to 150 mm, with a linear or spiral groove. The outer wall has cooling water channels and a feeding window. In order to complete the assembly, it should be inserted into the water jacket of the barrel. >>Learn More About our water jacket

Grooved feed barrels increase friction in the barrel more effectively. Extruders use this to get faster feed rates, increase conveying capacity, and increase discharge speed. In order to improve feed efficiency when processing olefin polymers like HDPE, PP pipes, and sheets, the barrel must be slotted. Groove feed barrel sleeves are more precise and flexible. For more abrasive or demanding applications, HUACHEN Screw can offer nitriding, alloy insert sleeves, and SKD sleeves technology.

We specialize in grooved feed barrel sleeves for

1. High efficiency high speed extrusion barrel

2. HDPE / PP extrusion

3. Pipes, sheets, recycling pelleting extrusion

4. Upgrading of normal barrels to high speed barrels is also available

Product specification

1. Grooved barrel sleeve materials: 38CrMoAlA, SKD, S38MnSIV

2. Plasma nitriding surface hardness: HV1000-1100

3. Plasma nitriding depth: ≥ 0.7mm

4. Alloy depth: 2-4 mm

5. Alloy surface hardness: HRC≥61

6. SKD sleeve surface hardness: ≥ HRC 62

7. SKD sleeve thickness: 6-10 mm

>>Learn more about our grooved feed barrel sleeve materials

123

Coco Shoes

Cocoshoes

coco sneakers

cocosneakers

Coco Shoes

Rep Shoes

Jordan 4

Coco Shoes

Coco kicks

Replica Shoes

Coco Shoes

Cocoshoes

Cocokick

Coco Shoes

Rep Shoes

Rep Balenciaga Track

Coco Shoes

Replica Balenciaga

Cocoshoes

Coco Shoes

Balenciaga Reps

Reps Shoes

Coco Shoes

reps jordan

Reps Shoes

Coco Shoes

Rep Shoes

Air jordan

Coco Shoes

Bathing Ape

Rep Shoes

Production time:

Complete grooved feed sleeve barrel within 30 days depending on the complexity of the part.

We offer a wide selection at good prices. You can trust the grooved feed barrel sleeves to be high quality. As the original China factory of single screw barrel, high speed extrusion screw barrels, we’re really good at what we do. Feel free to contact us if you have any questions.