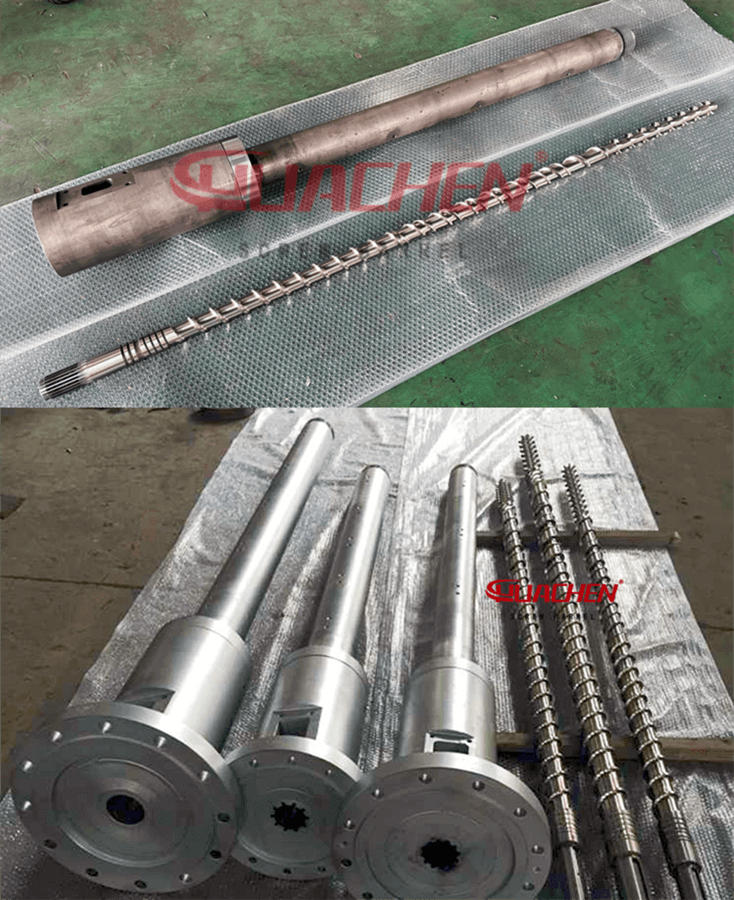

High Speed Screw And Barrel For HDPE Pipe Extrusion

● PE, HDPE, PP

● Pipe, film, pellets making

● Min. Order (MOQ): 1 screw + 1 barrel + 1 water jacket

● High speed screw barrel, semi high speed screw barrel, barrier screw, Maddock screw, screw mixer head, grooved feeding barrel

You Need Better high speed screw barrel at Good Price!

- Product Detail

High speed extrusion screw barrel is used in the plastic processing industry. It has many advantages, such as fast feeding, good mixing effect, low energy consumption, easy operation, etc.

D45 D65 D75 high speed extrusion screw barrel for HDPE pipe line

Applications: HDPE pipe, HDPE sheet, PPR water supply pipe

Features

The high speed design screw uses a special type of extrusion screw. This screw is a combination of a barrier screw, a Maddock mixer element screw, and a screw mixer head structure. There is a grooved feed barrel and a forced cooling water jacket in the barrel. Screws and barrels of this type could provide useful features.

1. Melting material could extrude at low temperatures.

2. Could improve the mixing of polymers.

3. Better control of the melting material, allowing for more variety of terminal products.

4. high speed extrusion screw barrels require higher quality materials and processing levels than standard screw barrels.

There are lots of high speed screws available for a variety of plastic raw materials. There are also different designs for different machinery brands and capacities.

Manufacture of high speed extrusion screw barrel

Classic 33 serious

| Model | Screw Diameter (mm) | L/D ratio | Screw speed Max. (rpm) | Motor required (KW) | Output (Kg/h) |

|---|---|---|---|---|---|

| HCGX45 | Ф45 | 33 | 10-150 | 20/30 | 100/120 |

| HCGX65 | Ф65 | 33 | 20-150 | 45/75/90 | 150/250/350 |

| HCGX75 | Ф75 | 33 | 20-150 | 90/110 | 350/450 |

| HCGX90 | Ф90 | 33 | 20-110 | 160/185 | 550/700 |

| HCGX120 | Ф120 | 33 | 20-90 | 280/315 | 950/1100 |

| HCGX150 | Ф150 | 33 | 20-75 | 355/400 | 1500 |

*Please check the actual screw barrel design with the salesperson before the order start.

High efficient 38 series

| Model | Screw Diameter (mm) | L/D ratio | Screw speed Max. (rpm) | Motor required (KW) | Output (Kg/h) |

|---|---|---|---|---|---|

| HCGX45 | Ф45 | 38 | 10-150 | 45 | 150-200 |

| HCGX65 | Ф65 | 38 | 20-150 | 110 | 350-450 |

| HCGX75 | Ф75 | 38 | 20-150 | 160 | 600-700 |

| HCGX90 | Ф90 | 38 | 20-110 | 250 | 1000-1100 |

| HCGX120 | Ф120 | 38 | 20-90 | 400 | 1500-1600 |

| HCGX150 | Ф150 | 38 | 20-75 | 450 | 1800-2000 |

Please check the actual screw barrel design with the salesperson before the order start.

High efficient 40 series

| Model | Screw Diameter (mm) | L/D ratio | Screw speed Max. (rpm) | Motor required (KW) | Output (Kg/h) |

|---|---|---|---|---|---|

| HCGS75 | Ф75 | 40 | 20-150 | 200 | 700-850 |

| HCGS90 | Ф90 | 40 | 20-110 | 315 | 1250-1350 |

| HCGS120 | Ф120 | 40 | 20-90 | 450 | 1900-2000 |

Please check the actual screw barrel design with the salesperson before the order start.

Spare parts for the following plastic machine brands

Oriplas, Jwell, and China plastic machine brands.

Parameter

1) Material: Premium 38CrMoAlA.

2) Plasma nitriding layer: 0.6-0.8mm

3) Nitriding time: more than 120 hours

4) Nitriding surface hardness: HV1000-1100.

5) Nitrided Brittleness: Less than Grade1.

6) Surface Roughness: Ra 0.4μm.

7) Screw Linearity: ≤0.015 mm

8) Alloy surface hardness: HRC≥61.

9) Alloy deepness: 4-6 mm

>>Learn more about our high speed extrusion screw barrel parameters

High speed screw barrel treatment available

1. Bimetallic barrel + bimetallic screw,

2. Nitrding barrel + bimetallic screw

3. Nitriding barrel + nitriding screw

High speed extrusion screw barrel related spare parts are available

1. Heaters and fans for screw barrel

2. Flange for screw barrel

3. Gearbox

Trading term

1. Business type: manufacturer, foreign trade company.

2. Origin: Zhoushan City, Zhejiang, China

3. Warranty: 12 months for fresh material.

4. International Commercial Terms: FOB, CFR, CIF, EXW

5. Screw and barrel Hs Code: 8477900000

6. Terms of Payment: T/T, L/C

7. Average Lead Time: stork model in 7 days. Peak season lead time: 45 days, Off season lead time: 33 days

8. Transport package: AA Grade Wooden Case

Screw and barrel buying guide

1. Inspection of original screws and barrels, and other related components.

2. Rebuilding Services to OEM specifications.

3. Modification services of screw designs to improve melting and mixing performance.

4. Emergency Service for an emergency turnaround service to minimize machine downtime.

About HUACHEN Screw

HUACHEN Screw has been a leading high speed extrusion screw barrel manufacturer in Zhoushan Jintang since 1993. With many years of experience in the design and processing of plastic machinery accessories, HUACHEN Screw can provide its customers with a wide range of services including made-to-order screw barrels, rebuilding, modification, and upgrade. Our company has also successfully exported and supplied screw barrels to customers worldwide.