Polyester/PET Yarn Monofilament Extrusion Screw Barrel

● PET, PP, PE, PA/nylon, etc.

● Min. Order (MOQ): 1 screw + 1 barrel

● Plastic filament yarn making. Monofilament making. Multifilament

● Fresh materials. Waste or recycled materials

● Anti-wear solution: Bimetallic barrel + bimetallic screw, nitriding barrel + bimetallic screw, nitriding screw barrel, chrome coating screw

You Need a Better Monofilament Extrusion Screw Barrel at Good Price!

- Product Detail

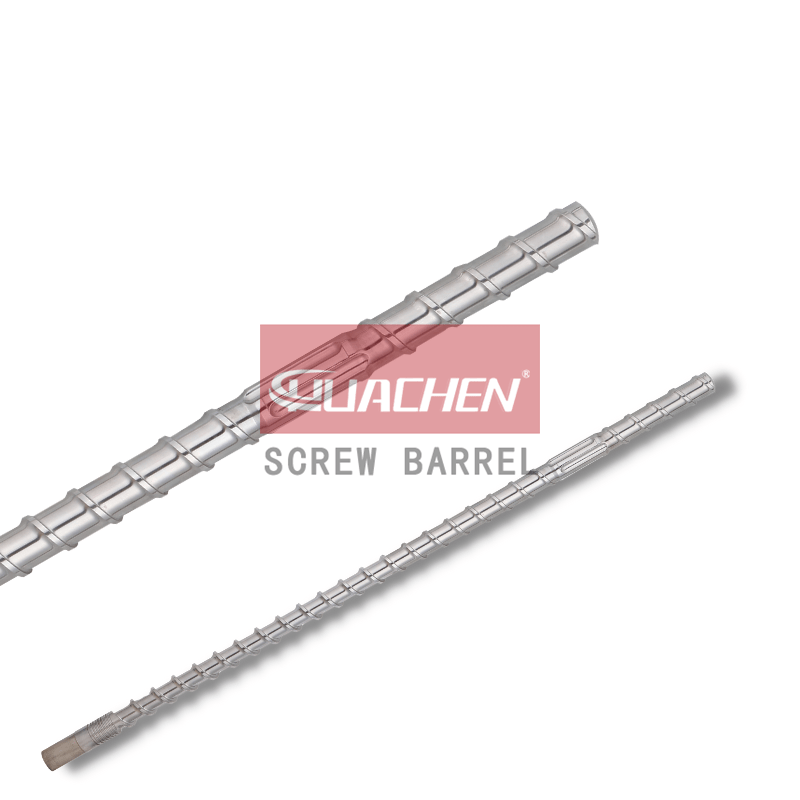

Single screw extruders are essential for producing polyester PET yarn monofilament. The yarn monofilament extrusion screw barrel is the core component of the polyester PET yarn monofilament extruder. Monofilament products’ performance and quality are determined by screw and barrel structural design and the strength of their materials.

Polyester PET yarn monofilament extrusion screw barrel

1. The screw and barrel are made from premium 38CrMoAlA. Processes using strict tempering and nitriding, the hardness of the screw barrel and various indicators of durability, allowing a longer service life. The screw and barrel are all machined using high precision CNC screw barrel milling machines. Each set of screw barrels has a high degree of consistency in extrusion.

2. With our large screw barrel machining equipment, we can quickly make quality large PET fiber monofilament extrusion screw barrels (D90, D105, D120, D160).

3. We offer three-stage monofilament screws and combination monofilament special screws as well. The screw and barrel feed section structure was optimized for stable feed and balanced output in the extrusion section, boosting plasticisation and extrusion efficiency. The melt will be compressed by increasing the melting and compression time. Monofilament will be more dense and homogeneous this way, ensuring quality.

4. We also offer special screws that can process recycled PET pellets for monofilament processing. Bimetallic alloy treatment and electroplating can be provided for transparent PET materials.

5. Screw and barrel construction ensures stable pressure fluctuations, stable temperatures, and stable extrusion volumes.

6. Screw barrels fit most models and are easy to install. You can also provide assembly information to our engineers for customizing your screw barrel.

Application

Polyester PET monofilament extrusion.

PP/PE mono-filament extrusion

Nylon PA monofilament extrusion

Multifilament extrusion machine

Filament and yarns extrusion machine

Manufacturer of monofilament extrusion screw barrel models

| Model | Screw diameter (mm) | L/D ratio | Screw speed Max. (rpm) | Motor required (KW) | Output (Kg/h) |

|---|---|---|---|---|---|

| HCS45 | Ф45 | 25/28/30 | 20-90 | 7.5 | 38 |

| HCS65 | Ф65 | 25/28/30 | 20-90 | 18.5 | 78 |

| HCS80 | Ф80 | 25/28/30 | 20-80 | 37 | 115 |

| HCS90 | Ф90 | 25/28/30 | 20-80 | 45 | 196 |

| HCS105 | Ф105 | 25/28/30 | 20-70 | 55 | 295 |

| HCS120 | Ф120 | 25/28/30 | 20-60 | 75 | 390 |

| HCS135 | Ф135 | 25/28/30 | 20-60 | 90 | 535 |

| HCS150 | Ф150 | 25/28/30 | 20-60 | 110 | 652 |

| HCS160 | Ф160 | 25/28/30 | 20-60 | 132 | 705 |

| HCS170 | Ф170 | 25/28/30 | 20-60 | 160 | 850 |

| HCS180 | Ф180 | 25/28/30 | 20-50 | 185 | 972 |

| HCS200 | Ф200 | 25/28/30 | 20-50 | 200 | 1050 |

*Please check the actual screw barrel design with the salesperson before the order start.

Parameters

1. Single screw diameter available: 45 mm to 200 mm

2. Single screw L/D ratio available: 25 to 30

3. Screw max. length: ≤10000 mm

4. Barrel max. out diameter: ≤350 mm

5. Based materials: Premium 38CrMoAlA

6. Plasma nitriding surface hardness: HV 1000-1100

7. Plasma nitriding depth: ≥ 0.7 mm

9. Nitriding fragility: less than Grade I.

10. Surface Roughness: Ra 0.4 μm

11. Screw Linearity: ≤ 0.015mm

12. Alloy depth: 4-6 mm

13. Alloy surface hardness: ≥ HRC 61

>>Learn more about our polyester PET monofilament Extrusion screw barrel parameters

The ultimate solution for abrasion and wear

Super durable level: bimetallic barrel and bimetallic screw;

Highly durable level: nitrided barrel and bimetallic screw;

Durable level: nitrided barrel and nitrided screws;

Hard chrome coating screw is an optional process.

Barrel with centrifugal casting process is an optional process.

Related extrusion screw barrel spare parts

1. Extrusion heaters. 2. Barrel blowers or fans. 3. Extrusion motor. 4. Extrusion gearbox for single screw

Production time

Complete set of polyester PET monofilament Extrusion screw barrel within 20-30 days depending on the complexity of the part.

HUACHEN Screw has been a leading manufacturer of polyester yarn monofilament extrusion screw barrel in Zhoushan Jintang since 1993. As one of the leading companies in designing and processing filament and yarn extrusion spare parts screw barrel, HUACHEN Screw can provide its customers with a wide range of services, including drawing rebuilding, design, modification, and customized screw barrels. Our company has also successfully exported and supplied screw barrels to customers worldwide. We are the China Origin Factory of polyester PET monofilament Extrusion screw barrel. If you have any questions, please feel free to contact us.