PVC Pipe Twin Parallel Screw Barrel

● PVC / UPVC / RPVC / CPVC

● Pipe making extrusion, virgin or recycled materials, compound materials

● Filler percentage with 30-50%, 50-100%, 100-150%, 150-200%

● Min. Order (MOQ): 2 screws + 1 barrel / Set

● Anti-wear solution: SKD sleeve fitted barrel + bimetallic screw, bimetallic barrel + bimetallic screw

You need better twin parallel screw barrel set at good price!

- Product Detail

In PVC pipe manufacturing, the counter rotating twin parallel screw barrel extruder is often used. It takes a dry mix of PVC and other auxiliary materials. The twin parallel screws turn the material into molten PVC, which is then shaped into pipes by moulds. Twin parallel screws are the core component that determines the quality of plasticised PVC and the stability of PVC pipe products. Our main clients are PVC pipe manufacturers, but we also supply spare parts to many extruder equipment machinery around the world.

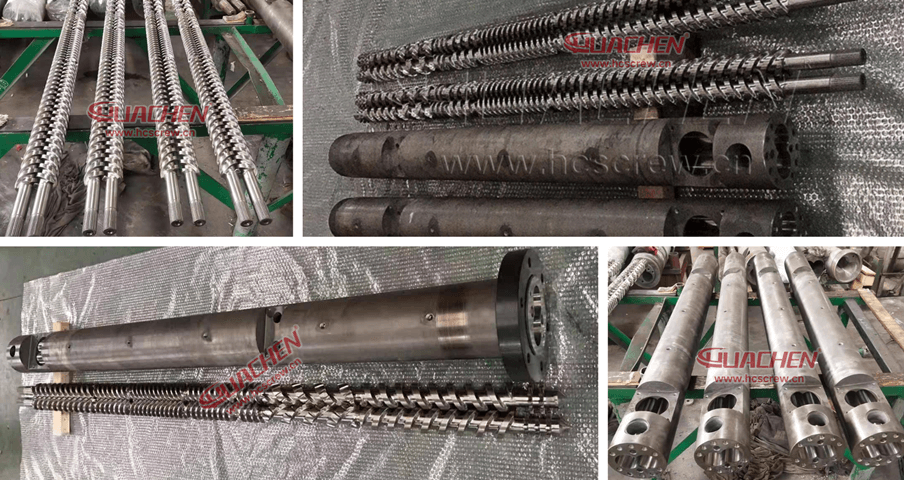

PVC pipe twin parallel screw barrel

1. We have twin parallel screw barrels for PVC pipes. Screw barrels are made from high quality alloy steel 38CrMoAlA that’s tempered, precision machined, and nitrided for hardness and corrosion resistance. Each screw and barrel is machined using high precision CNC screw and barrel milling machines to ensure a high degree of consistency in extrusion performance. Screws and barrels have a smooth surface, and there are no gaps to gather material.

2. There’s a high level of corrosion and wear resistance on the screw barrel set. Bimetallic alloy anti-wear treatment is applied to the top surface of the screw flight in the compression, metering, venting, and mixing sections. The barrels can be supplied with a dual alloy groove surface strengthening process to make them more abrasion-resistant. Furthermore, we can provide a customised service for SKD sleeve fitted barrel.

3. We offer optimized screw designs that help mix the PVC pipe material well, increase plasticisation, improve extrusion volume, and provide good venting performance. In this way, you’ll get a great PVC pipe surface.

4. Our factory is equipped with a complete set of twin parallel screw barrel production processes, which allows us to produce large size twin parallel screw barrels potentially saving you production cost. Please contact us for the latest stock availability and screw barrel price on some screw barrel models.

Applications

Solid wall PVC pipe twin parallel screw extrusion machine; corrugated wall PVC pipe extrusion machine; UPVC pipe twin parallel screw extrusion; CPVC pipe making machine.

Manufacture of PVC pipe twin parallel screw barrel

| Extrusion brand | Screw barrel models |

|---|---|

| CINCINNATI | AGROS – 72 / 93 / 114 / 136 |

| KRAUSS MAFFEI | KMD – 75 / 90 / 110 / 130 |

| BATTENFIELD | BEX – 65 / 68 / 90 / 92 / 107 / 130 |

| KABRA | 52 / 65 / 68 / 90 / 92 / 110 / 135 / 168 |

| WINDSOR | KTS – 52 / 65 / 71 / 91 / 110 / 135 |

Twin parallel screw barrel models in the stork

| φ52/25 | φ60/25 | φ75/36 | φ90/36 | φ107/28 |

| φ107/28 | φ120/26 | φ130/28 | φ135/28 | φ160/33 |

Popular PVC twin parallel screw barrel models

| Model | Screw diameter (mm) | L/D ratio | Screws rotation speed ( RPM) | Extruder motor power | PVC capacity (kg/h) |

|---|---|---|---|---|---|

| HCPS-75 | 75 | 26-36 | 0-45 | 45-55 | 220-350 |

| HCPS-90 | 90 | 26-36 | 0-45 | 55-75 | 280-460 |

| HCPS-110 | 110 | 26-36 | 0-45 | 75-110 | 350-650 |

| HCPS-120 | 120 | 26-36 | 0-45 | 110-132 | 500-800 |

| HCPS-130 | 130 | 26-36 | 0-45 | 132-145 | 680-1000 |

Twin Parallel Screw Barrel Parameter

1) Twin parallel screw diameters available: 35-110 mm; 2) twin parallel screw L/D ratio available: 15 to 36; 3) Material: Premium 38CrMoAlA, SKD11; 4) Plasma nitriding layer: 0.7 mm; 5) Nitriding time: more than 120 hours; 6) Nitriding surface hardness: ≥HV1000; 7) Nitrided Brittleness: Less than Grade1; 8) Surface Roughness: Ra 0.4μm; 9) Screw Linearity: ≤0.015mm; 10) Alloy surface hardness: HRC≥61; 11) Alloy deepness: 1.5-4mm; 12) SKD sleeve surface hardness: HRC≥62; 13) SKD sleeve thickness: 6-10mm.

>>Learn more about our PVC pipe twin parallel screw barrel parameters

The ultimate solution for abrasion and wear

-Level 2, SKD sleeve fitted barrel and bimetallic screws;

-Level 1, bimetallic barrel and bimetallic screws.

-Level 1, nitriding barrel and bimetallic screws.

About delivery

The PVC pipe twin parallel screw barrels are self-produced and are expected to be dispatched within 15-40 days, depending on the complexity of the part. This model is also available in stock, as well as on a rolling basis. Actual production times may cause dispatch times to be earlier or later. Please consult our sales staff for specific delivery times, which also gives us more time to ensure quality.

Services

1. Inspection of original screws and barrels, and other related components.

2. Rebuilding Services to OEM/ODM specifications.

3. Modification services of screw designs to improve melting and mixing performance.

4. Emergency Service for an emergency turnaround service to minimize machine downtime.

HUACHEN Screw has been a leading twin screw barrel manufacturer in Zhoushan Jintang since 1993. Our services include drawing rebuilding, design, modification, and customized screw barrels. Besides manufacturing screw barrels, we export them all over the world. It is the China origin factory of PVC pipe twin parallel screw barrel. If you have any questions, please feel free to contact us.