SPC Stone Plastic Composite Flooring Extruder Conical Twin Screw Barrel

● SPC / RVP, virgin or recycled materials

● sheet, board, plank, flooring, decking

● Filler ratio of 200-300%, and greater than 300%.

● Min. Order (MOQ): 2 conical screws + 1 barrel

● Based material: Premium 38CrMoAlA tempered and nitrided, SKD11

● Anti-wear solution: SKD sleeve fitted barrel + bimetallic screw, bimetallic barrel + bimetallic screw, chrome coating screw, ceramic alloy screw

You Need Better Conical Twin Screw Barrel at Good Price!

- Product Detail

Stone plastic composite (SPC) is a new type of eco-friendly rigid vinyl plank flooring. The product is heated, laminated, and embossed in one process on a three- or four-roller calendar with PVC wear layer, color film, and substrate board. Raw materials, processing technology, and equipment capacity determine the performance of SPC flooring. As SPC flooring has a high calcium content as well as high plasticising requirements, special screw and barrel designs are required, as well as the highest quality anti-wear material. HUACHEN Screw, a leading SPC flooring screw barrel manufacturer. We worked with SPC flooring equipment companies to develop more usable conical twin screw barrels for SPC flooring based on their experience.

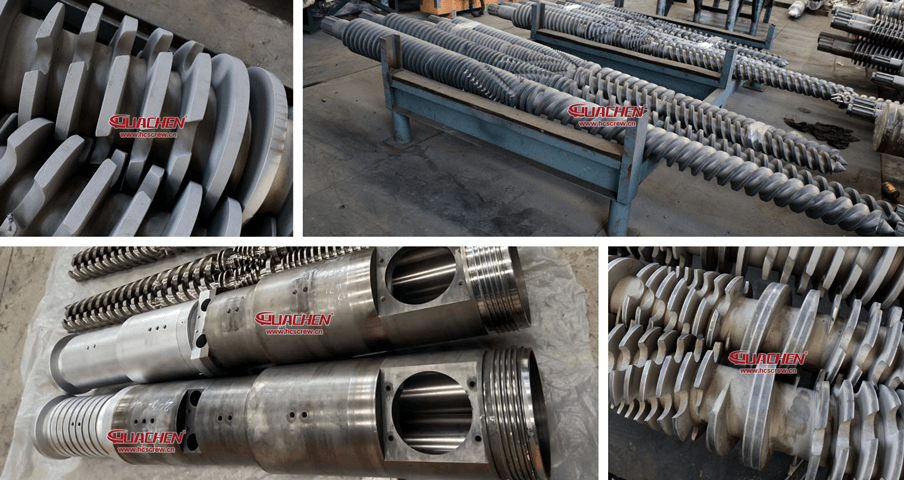

SPC stone plastic composite flooring extruder conical twin screw barrel

HUACHEN’s SPC flooring conical twin screw barrel series has the following advantages over traditional PVC conical twin screw barrel:

1. SPC raw materials have a lot of calcium powder filling and poor flow. We designed our SPC conical twin screws for low shear, high mixing, and high conveying. The PVC material gets fully plasticized and melted in a low-temperature environment, improving the look of SPC flooring.

2. Better feeding and stable extrusion. This screw has a hydrodynamic design and a long feed section and a barrier section to increase the extruder’s feed and extrusion capacity. As the machine is capable of preparing thick SPC sheets and supporting in-line lamination, the production process remains continuous and stable.

3. The SPC flooring screw and barrel are all made from high quality alloy steel, 38CrMoAlA, tempered and nitrided. To extend the life of the screw, the screw flights top surface is coated with bimetallic alloy, and ceramic tungsten alloy coating. The barrel is fitted with a replaceable SKD sleeve fitted barrel. The SKD sleeve is vacuum quenched and then nitrided to achieve higher wear resistance. It’s easy to replace the SKD sleeve when it wears out with a new barrel assembly. It reduces production costs.

4. We machine all screws and barrels on CNC screw barrel milling machines. Keeping the screws and barrels consistent ensures high extrusion performance. Screws and barrels have smooth surfaces so material won’t stick.

Application

SPC stone plastic composite sheet or board extruder; SPC composite panel extruder; SPC composite profile extruder; Kingshine, Haobang, and China SPC composite flooring extrusion machine brands.

Manufacture of SPC flooring extruder conical twin screw barrel

| Model | Speed (RPM) | Motor (KW) | Capacity (kg/h) | Screw length (mm) | Barrel length (mm) | Weight (kg) | Package dimension (m) |

|---|---|---|---|---|---|---|---|

| HCZS80/156 | 75 | 55 | 450 | 2116 | 1850 | 775 | 2.2*0.4*0.5 |

| HCZS92/188 | 34.7 | 110 | 750 | 2805 | 2520 | 1500 | 3.0*0.5*0.6 |

| HCZS 110/220 | 34.7 | 200 | 1250 | 3332 | 2995 | 2100 | 3.4*0.5*0.5 |

>> We offer standard and high efficiency conical twin screw barrel models and more. All of them use standard assembly dimensions and are easy to install. We’ve fine-tuned SPC conical twin screw barrel designs based on region and country. Get in touch if you want to know more.

Parameters

1) Material: Premium 38CrMoAlA, UNS K24065, SACM645, 41CrAlMo7-10, SKD11. 2) Plasma nitriding layer: 0.6-0.8mm. 3) Nitriding time: more than 120 hours. 4) Nitriding surface hardness: HV1000-1100. 5) Nitriding Brittleness: Less than Grade 1. 6) Surface Roughness: Ra 0.4μm. 7) Screw Linearity: ≤0.015mm. 8) Alloy surface hardness: HRC≥61. 9) Alloy deepness: 6-8mm. 10) SKD sleeve surface hardness: HRC≥62. 11) SKD sleeve thickness: 6-10mm

>>Learn more about our SPC composite flooring extruder conical twin screw barrel parameters

Production time

Stork model in 7 days. Peak season lead time within 45 days, and off season lead time within 33 days depending on the complexity of the part.

HUACHEN Screw has been a leading conical twin screw barrel manufacturer in Zhoushan Jintang since 1993. We’re members of the China Building Decoration and Resilient Flooring Association and directors of the China Jintang Plastic Screw Industry Association. HUACHEN Screw can provide its customers with a wide range of services, including drawing rebuilding, design, modification, and customized screw barrels. We have also successfully exported and supplied screw barrels to customers throughout the world. We are the China origin factory of SPC stone plastic composite flooring extruder conical twin screw barrel. If you have any questions, please feel free to contact us.