Expert Maintenance Tips for Long-Lasting Bimetallic Alloy Screw Barrels

Date:2023-3-31 Author:hcscrew

Discover the secrets to keeping your bimetallic alloy screw barrel in top shape with our expert maintenance tips. Learn how to extend the lifespan of your single screw barrel and avoid costly downtime.

As an extruder operator, you know the importance of keeping your production line running smoothly. One of the key components of your extruder is the screw barrel. This barrel melts and homogenizes raw material before extruding through a die. Bimetallic alloy screw barrels, in particular, are widely used due to their excellent wear and corrosion resistance. However, like all equipment, bimetallic alloy screw barrels require proper maintenance to ensure optimal performance and longevity. In this article, we’ll explore expert tips for maintaining bimetallic alloy screw barrels and keeping your extruder running smoothly.

Understanding Bimetallic Alloy Screw Barrels

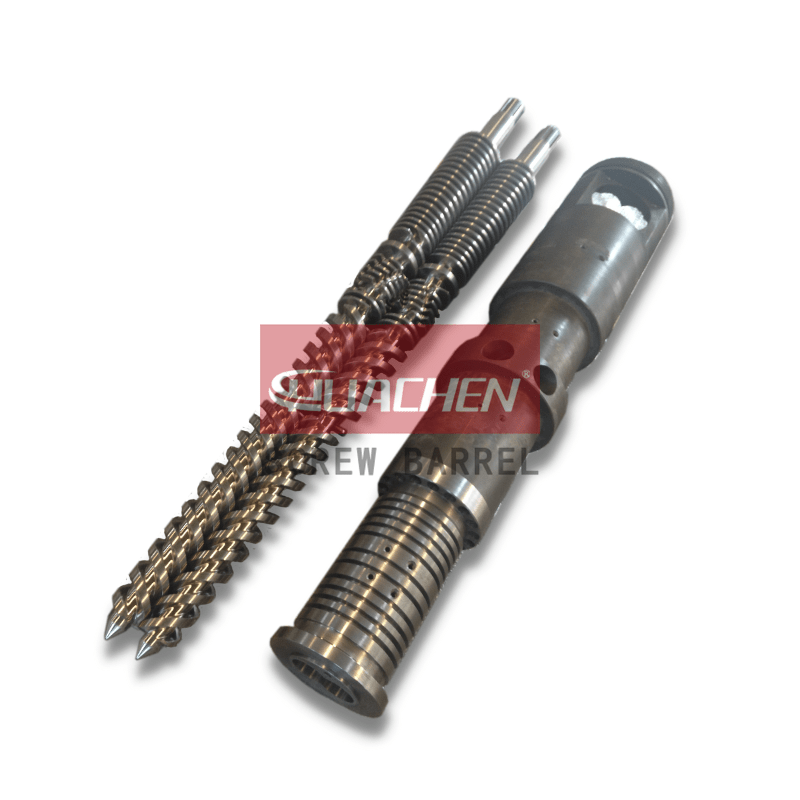

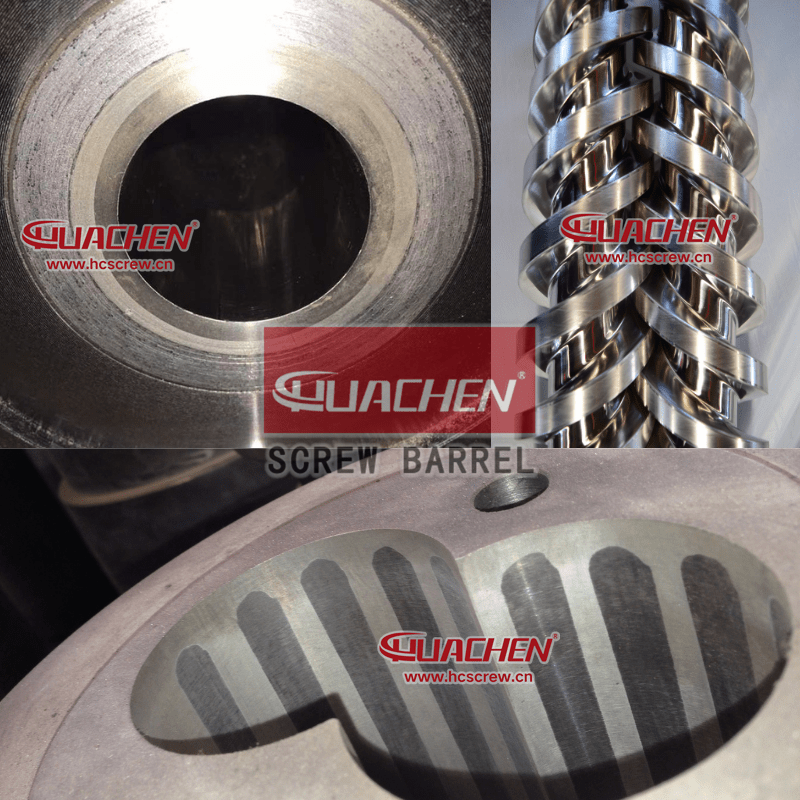

Bimetallic alloy screw barrels are made by bonding a layer of wear-resistant alloy to the inner surface of a barrel made of a different material. This design provides the advantage of both worlds, combining the toughness and durability of the base material with the wear resistance and corrosion resistance of the alloy layer. Bimetallic alloy screw barrels are widely used in extrusion processes involving abrasive materials, high temperatures, and corrosive environments. Single screw barrel extruders use bimetallic alloy screw barrels due to their long lifespan.

Best Practices for Bimetallic Alloy Screw Barrel Maintenance

To ensure that your bimetallic alloy screw barrel lasts as long as possible, it is imperative to follow the best maintenance practices. This includes regular inspection, cleaning, and lubrication. Regular inspection can help detect issues before they become major problems. Cleaning the screw barrel is essential to remove material buildup. This can cause uneven wear and tear and affect the extruded product quality. Lubrication reduces friction and wear, but it is key to using the right type of lubricant for your specific screw barrel. This is to avoid damage to the alloy layer.

Bimetallic screws cause screw wear and tear causes and ways to reduce wear

1. For each plastic material, there is an ideal plasticization on the processing temperature scale, so should control the barrel processing heat so that it is close to this temperature. In the first half of the barrel, granular plastic will reach the filling section; in the filling section, dry friction will appear. When these plastics are underheated and unevenly melted, it is easy to wear the inner wall of the barrel and the exterior of the screw. Similarly, in the compression section and homogenization section, if the plastic melt condition is disorderly and uneven, it will also result in an increase in wear and tear.

2. the speed should be properly adjusted. Some plastics contain reinforcing agents, such as glass fibres, minerals, or other fillers. These substances are often more abrasive to metal than molten plastic. When extruding these plastics, the shear force on the plastic is increased if high speeds are used. At the same time, reinforcement will result in more torn fibres, which contain sharp tails and increase the abrasive force considerably. Inorganic minerals also scrape at high speed on the metal surface.

Bimetallic screw for daily protection

1. Do not start the machine before the barrel screw reaches the pre-set temperature.

2. to avoid metal fragments and debris from entering the hopper, if the processing of recycled material, it is necessary to add a magnetic hopper to avoid iron chips, etc. Into the barrel.

3. When using anti-saliva, make sure the plastic in the barrel is completely melted to avoid damage to the drive system parts when the screw is backed up.

4. When using fresh plastic, the barrel should be cleaned of remaining material.

5. When the molten plastic temperature is normal but it constantly appears with black spots or discolouration, you should check the screw.

6. In processing, try to make the material plasticized evenly, do not let the metal foreign body mixed into the plastic, reduce the screw barrel rotation torque force.

Customizing Your Bimetallic Alloy Screw Barrel

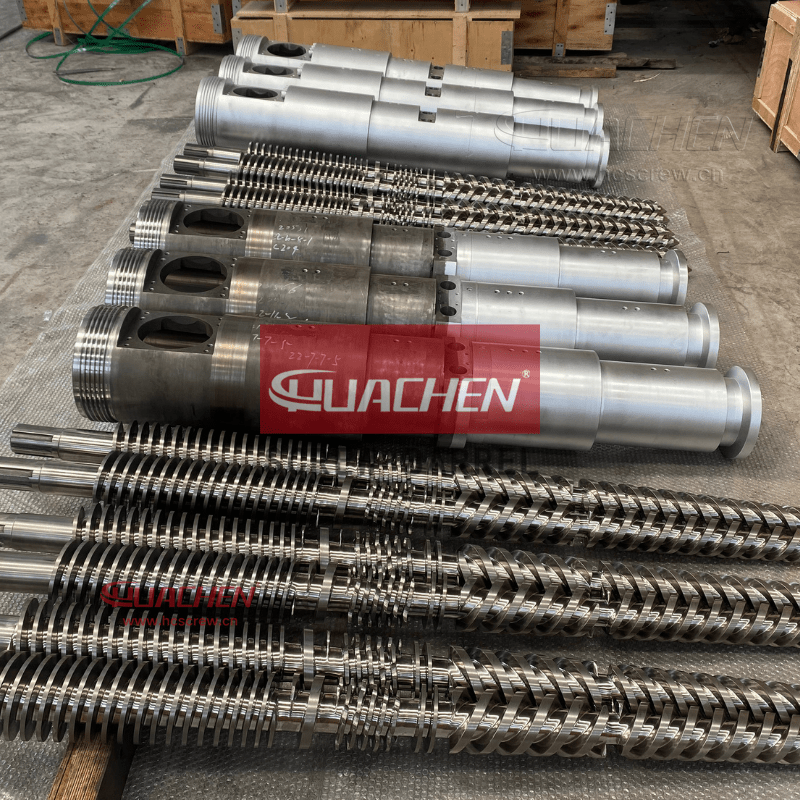

Customizing your bimetallic alloy screw barrel can also prolong its lifespan and optimize its extrusion performance. Working with a screw barrel manufacturer to design a customized screw barrel that meets the specific needs of your production line can improve productivity and reduce downtime. A customized bimetallic alloy screw barrel can be tailored to the specific materials being extruded and the processing conditions. This results in improved efficiency and product quality.

Conclusion

In conclusion, maintaining your bimetallic alloy screw barrel is key to consistent extrusion performance and cost savings in the long run. Following expert maintenance tips, such as regular inspection, cleaning, and lubrication, can prolong the lifespan of your screw barrel. Additionally, customizing your screw barrel can optimize extrusion performance and productivity. By prioritizing maintenance and working with a reputable screw barrel manufacturer, you can ensure that your production line runs smoothly and efficiently for years to come.

You May Also Like

| Bimetallic Alloy Screw Barrel ↗ Get details and latest price of bimetallic alloy screw barrel, heavy duty screw barrel, anti wear screw barrels and more at HUACHEN |

| Hard Chrome Plating Screw Barrel ↗ Upgrade the performance of your extrusion machine with our hard chrome plated screw barrels. Our custom-made barrels are designed to enhance durability and increase the lifespan of your machine. Get in touch to learn more. |

| Ceramic Coating Alloy Screw Barrel ↗ Get details and latest price of ceramic coating alloy screw barrel, heavy duty ceramic tungstem screw barrels for SPC RVP, and more at HUACHEN |

| SKD Screw Barrel ↗ Get details and latest price of SKD sleeve fitting screw barrel, high-filled PVC twin screw extrusion parts, anti wear screw barrel at HUACHEN |

About the screw barrel Factory: HUACHEN

HUACHEN Screw has been a leading extrusion screw barrel manufacturer in Zhoushan Jintang since 1993. As one of the leading companies in designing and processing conical and parallel twin screw barrels, high speed extruder screw barrel, HUACHEN Screw can provide its customers with a wide range of services, including drawing rebuilding, design, modification, and customized screw barrels. Our company has also successfully exported and supplied screw barrels to customers worldwide.

>>Learn more about our company

TAGS

HUACHEN Screw barrel recent post

- Boosting Efficiency and Quality: HUACHEN Screw Barrel’s Unmissable Showcase at HanoiPlas 2023

- Pipe Extrusion Operation: Best Practices for High-Quality Products

- Expert Maintenance Tips for Long-Lasting Bimetallic Alloy Screw Barrels

- Reviving Your Extruder: The Importance of Choosing the Right Screw Barrel Replacement

- Solutions to Common Production Problems for Rigid PVC Profiles and Pipes

- Customized Twin Screw Barrel with Internal Bore Grooves Sprayed with Bimetallic Alloy

- Troubleshooting Vent Flow Material Problems in PVC Profile Formation with Conical Twin Screw Extruders

- A Comprehensive Guide to Popular PVC Profiles and Their Production Methods

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;