Troubleshooting Vent Flow Material Problems in PVC Profile Formation with Conical Twin Screw Extruders

Date:2023-3-12 Author:hcscrew

Learn how to resolve vent flow material problems when forming PVC profiles with conical twin screw extruders. Our comprehensive guide provides practical solutions to ensure smooth and efficient extrusion processes.

When producing PVC profiles using a conical twin screw barrel, a common problem that may arise is vent flow issues. Vent flow problems occur when air and moisture are not properly expelled from the barrel during the extrusion process, leading to defects in the final product. In this blog, we will discuss some of the causes of vent flow material problems and provide solutions for fixing and preventing them.

Causes of vent flow material problems

1 What should be done if the conical twin screw extruder vents material while forming PVC profiles?

To ensure the quality of the plasticised material and the quality of the product, a conical twin screw barrel has two venting holes in the barrel. These venting holes facilitate the discharge of gases or volatiles from the material. In the forming process, if the material emerges from the venting holes, it can be easily blocked. As a result, extrusion fluctuates, affecting stability and PVC profile quality.

The main causes of extruder venting and powder extraction are:

① The amount of material supplied to the conical twin screw barrel does not correspond to the amount of extruded material, and the amount of material supplied to the extruder exceeds the amount expended by the conical twin screw. As a result of pressure, excess material will inevitably be squeezed into the low pressure vent, causing it to come out of the vent and eventually block it – this is the most common reason why conical twin screw extruders vent materials.

② There is an unreasonable amount of temperature control during extrusion. The material reaching the extruder venting area is overplasticized. Volatile components and gas are wrapped in internal material, making it difficult to escape. As the pressure in the venting area drops suddenly, the melt will result in a relatively large expansion. Due to this, the vent hole parts may grind down, and the vent hole may remain set or scorched, blocking the venting.

Usually, the solutions are:

① Ensure that the host material supply area and compression area process temperatures are appropriate to ensure an appropriate level of plasticization, and control the material density in the exhaust area to be at 1.0 ~ 1.2g/ml;

② The feed screw speed and main screw speed must be controlled appropriately, so that the extrusion volume and feed volume are almost equal;

③ Ensure that the extruder venting vacuum is controlled according to the requirements, and clean up the vent port as soon as possible.

2 When PVC profiles are extruded with conical twin screws, why does powder escape from the venting holes? How to solve it?

The reasons for the extraction of powder from the venting hole are as follows:

① The temperature of the material supply area and the compression area is too low, and the material is not sufficiently plasticized;

② The channel through which the material flows is not airtight enough in front of and behind the venting hole.

Solutions:

① Improve the temperature of the extrusion barrel supply area and compression area to ensure the material’s plasticization quality;

② Make sure that the plasticization of the material is uniform by controlling the speed of the extruder screw and feed speed;

③ Seal the extruder quantitative feed observation port properly to ensure that the channel that the material flows through is airtight before and after the venting hole.

3 When producing the PVC profile, material is extruded from the venting hole. Why is this happening? Do you know that the torque of the extruder increases at the same time? How can the problem be solved?

The main reasons for this are:

① adding material too fast leads to insufficient shear heat to balance the amount of heat needed to increase feed material, resulting in poor plasticization;

② Extrusion speed is too fast, increased shear heat is insufficient to balance the heat lost by the material in the feed section and compression section to reduce the residence time, resulting in poor plasticization;

③ when the formula uses CPE impact modifier, the amount of processing aids added is too small. When the plasticization is poor, the material has poor friction performance.

When the problem of venting material, caused by a variety of possible causes, requires comprehensive analysis and appropriate measures. When the material comes out of the vent hole and the extruder torque rises, the solution should be to reduce the speed of the feed or the speed of the extruder screw(the conical twin screw), or to increase the processing aids to improve the plasticisation quality of the material.

4 Why does the extruder torque drop during the extrusion of PVC profiles with venting material? How should we proceed?

There are several reasons why the material comes out of the vent hole and the torque decreases on the extruder:

① Too much lubricant in the formula, too much movement in the extruder, too fast extrusion speed, and poor plasticization at the vent hole;

② There is too large an axial clearance between the extruder screw and the screw barrel, causing serious leakage;

③ the temperature of the feed section and the compression section of the screw is too high, which causes the material to be “over-plasticized”. After the compression section’s first pressure peak, it transformed into molten material, which emitted into the venting hole after the stress was released, volume expanded, adhesion developed in the screw prism end face, and when the venting section of the barrel rotated the screw, it scraped down the wall of the venting hole, accumulating to a certain extent from overflow.

The solution is mainly:

① It is necessary to adjust the PVC profile formula, to increase the role of lubricants;

② Re-adjust the extruder screw and barrel clearance, and replace the screw or barrel as necessary;

③ When the material in the venting hole is “over plasticized,” the barrel temperature should be reduced or feeding and extrusion speeds should be adjusted.

Conclusion

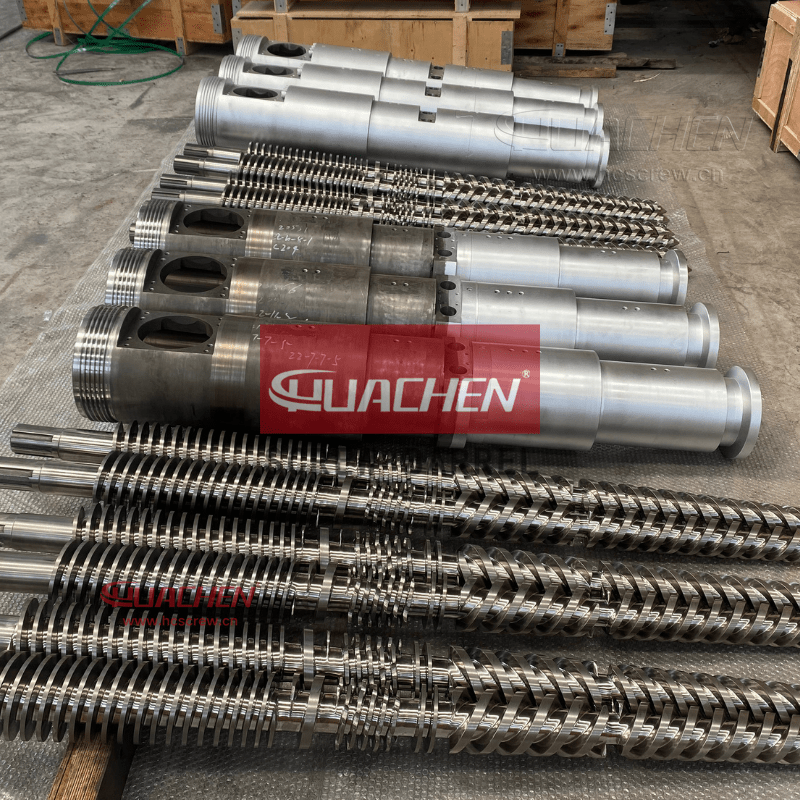

In conclusion, vent flow problems can be a common problem when using a conical twin screw barrel to produce PVC profiles. The screw barrel is again the most critical link in the commissioning of the extruder in general. We evaluated the screw barrels and extrusion systems of some new customers who approached us with this problem. It has been found that unreasonable problems with screw and barrel construction are quite common. It includes poorly constructed screw flights and an internal screw cooling system that is poorly designed. As well as barrel detailing issues. The screw barrel may seem simple, but in fact, there is still a lot to learn. By properly addressing the root causes of the problem and taking corrective actions, vent flow issues can be prevented and fixed, resulting in a high-quality final product.

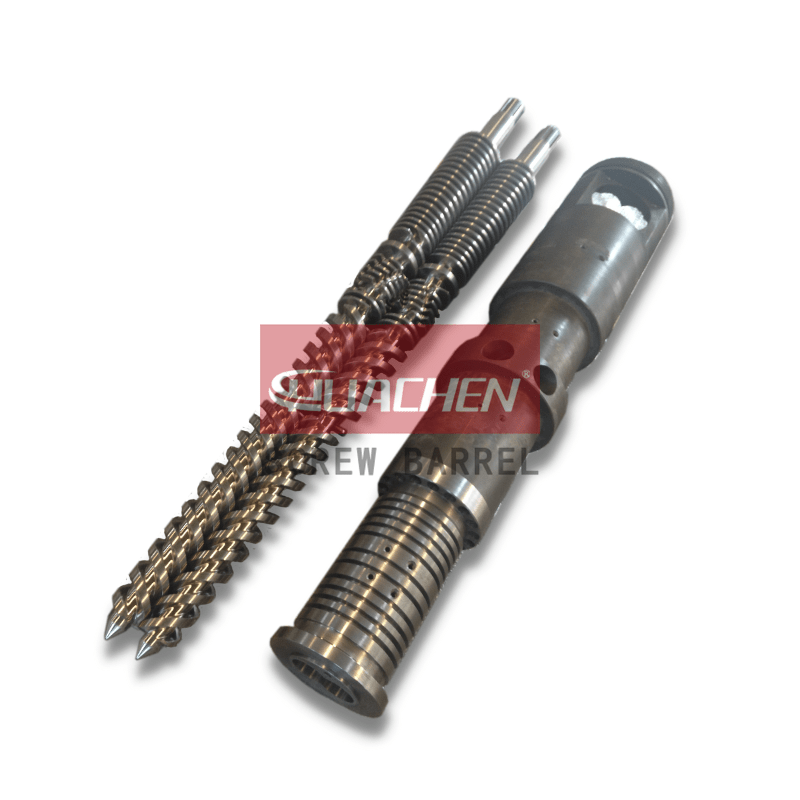

About the screw barrel Factory: HUACHEN

HUACHEN Screw has been a leading conical twin screw barrel manufacturer in Zhoushan Jintang since 1993. As one of the leading companies in designing and processing twin screw barrels, high speed extruder screw barrel, HUACHEN Screw can provide its customers with a wide range of services, including drawing rebuilding, design, modification, and customized screw barrels. Our company has also successfully exported and supplied screw barrels to customers worldwide.

>>Learn more about our company

You May Also Like

| PVC Profiles Extrusion Screw Barrel ↗ Get details and quote for PVC profile extrusion screw barrel. We offer a wide variety of anti-wear screw barrels for many profile extrusions. |

| RPVC, CPVC, UPVC Screw Barrel ↗ Get details and latest price of RPVC, CPVC, UPVC PVC screw barrel, high-speed design, better anti-wear anti-corrosion screw barrel at HUACHEN. |

| 25 PVC Pipe And Other PVC Products Making Formulas ↗ Introduce 25 typical PVC product formulas in PVC extruding process. Such as PVC pipe, PVC panel production formula, PVC sheet, PVC profile. |

TAGS

HUACHEN Screw barrel recent post

- Boosting Efficiency and Quality: HUACHEN Screw Barrel’s Unmissable Showcase at HanoiPlas 2023

- Pipe Extrusion Operation: Best Practices for High-Quality Products

- Expert Maintenance Tips for Long-Lasting Bimetallic Alloy Screw Barrels

- Reviving Your Extruder: The Importance of Choosing the Right Screw Barrel Replacement

- Solutions to Common Production Problems for Rigid PVC Profiles and Pipes

- Customized Twin Screw Barrel with Internal Bore Grooves Sprayed with Bimetallic Alloy

- Troubleshooting Vent Flow Material Problems in PVC Profile Formation with Conical Twin Screw Extruders

- A Comprehensive Guide to Popular PVC Profiles and Their Production Methods

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;