Reviving Your Extruder: The Importance of Choosing the Right Screw Barrel Replacement

Date:2023-3-23 Author:hcscrew

Is your extruder not performing up to par? The solution could be as simple as choosing the right replacement screw barrel. Read on to learn about the importance of working with a trusted screw barrel manufacturer and the benefits of customizing your screw barrel for optimal performance.

If you’re a manufacturer that uses extruders to make plastic products, it’s essential to make sure your equipment runs efficiently. The screw barrel is a key component of the extrusion process. Ensuring that it is in excellent condition is critical to maintaining productivity and quality. In this article, we’ll discuss the importance of choosing the right replacement screw barrel for your extruder. We’ll focus on the benefits of working with a trusted screw barrel manufacturer and the option to customize your screw barrel for optimal performance.

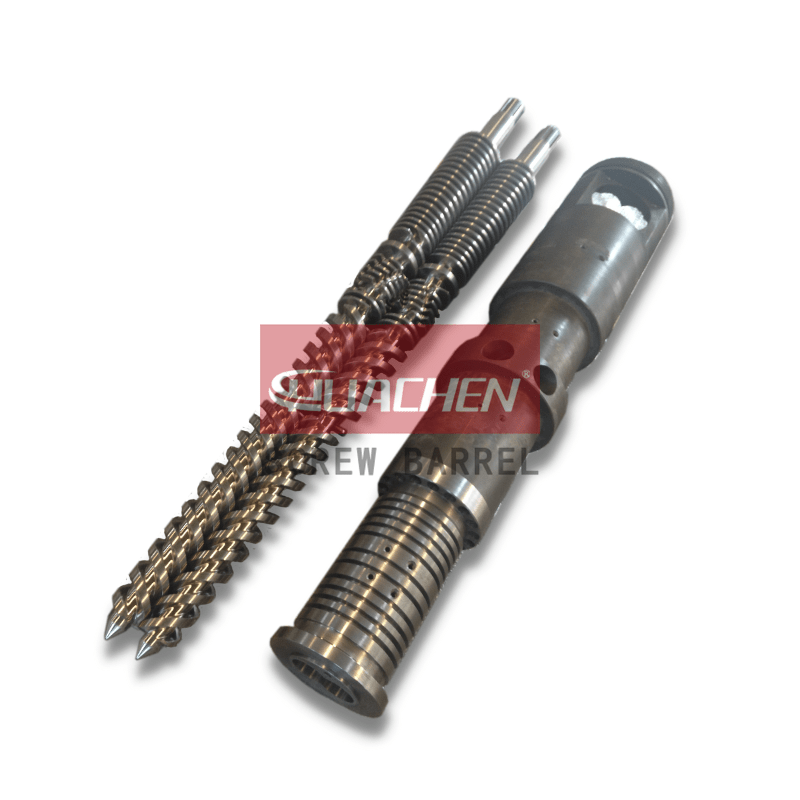

The Screw Barrel’s Role in Extrusion

The screw barrel is responsible for feeding, melting, mixing, and pumping the plastic material through the extruder. Over time, wear and tear can cause the screw barrel to deteriorate, leading to reduced productivity, poor quality, and increased downtime. It is important to recognize the signs that your screw barrel needs to be replaced, such as corrosion, erosion, and poor mixing efficiency.

Choosing the Right Replacement Screw Barrel

When choosing a replacement screw barrel, it is essential to work with a trusted screw barrel manufacturer. They will have the technical expertise and experience to advise you on the best material, design, and manufacturing process for your specific needs. A high-quality replacement screw barrel will improve your extruder’s performance but also increase its lifespan and reduce maintenance costs.

Customize Your Screw Barrel

One of the greatest benefits of working with a screw barrel manufacturer is the option to customize your screw barrel for optimal performance. A customized screw barrel can be designed to meet your specific requirements, such as higher wear resistance or improved mixing efficiency. You can work closely with your screw barrel manufacturer to identify the exact needs of your production process. You can also develop a custom solution that works best for you.

In addition to improving the performance of your extruder, customizing your screw barrel can also save you money. By identifying the specific needs of your production process and developing a custom solution, you can reduce material waste and improve efficiency. For example, if you are experiencing wear and tear on your screw barrel due to the specific materials you are using, a customized screw barrel can be designed with higher wear resistance to ensure a longer lifespan.

Benefits of Upgrade to a High-Quality Replacement Screw Barrel

Upgrading to a high-quality replacement screw barrel has numerous benefits. It can improve the efficiency and accuracy of the extrusion process, resulting in higher quality products and increased productivity. In addition, a high-quality replacement screw barrel can reduce maintenance costs, increase extruder lifespan, and minimize downtime. By working with a trusted screw barrel manufacturer and customizing your screw barrel, you can ensure that your extruder is running at peak performance.

Conclusion

In conclusion, choosing the right replacement screw barrel is critical for reviving your extruder’s performance. By working with a trusted screw barrel manufacturer and customizing your screw barrel, you can get the best possible product for your specific needs. Whether you are looking to improve efficiency, increase productivity, or reduce downtime, upgrading to a high-quality replacement screw barrel is a smart investment for any extruder user.

About the screw barrel Factory: HUACHEN

HUACHEN Screw has been a leading extrusion screw barrel manufacturer in Zhoushan Jintang since 1993. As one of the leading companies in designing and processing conical and parallel twin screw barrels, high speed extruder screw barrel, HUACHEN Screw can provide its customers with a wide range of services, including drawing rebuilding, design, modification, and customized screw barrels. Our company has also successfully exported and supplied screw barrels to customers worldwide.

>>Learn more about our company

TAGS

HUACHEN Screw barrel recent post

- Boosting Efficiency and Quality: HUACHEN Screw Barrel’s Unmissable Showcase at HanoiPlas 2023

- Pipe Extrusion Operation: Best Practices for High-Quality Products

- Expert Maintenance Tips for Long-Lasting Bimetallic Alloy Screw Barrels

- Reviving Your Extruder: The Importance of Choosing the Right Screw Barrel Replacement

- Solutions to Common Production Problems for Rigid PVC Profiles and Pipes

- Customized Twin Screw Barrel with Internal Bore Grooves Sprayed with Bimetallic Alloy

- Troubleshooting Vent Flow Material Problems in PVC Profile Formation with Conical Twin Screw Extruders

- A Comprehensive Guide to Popular PVC Profiles and Their Production Methods

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;